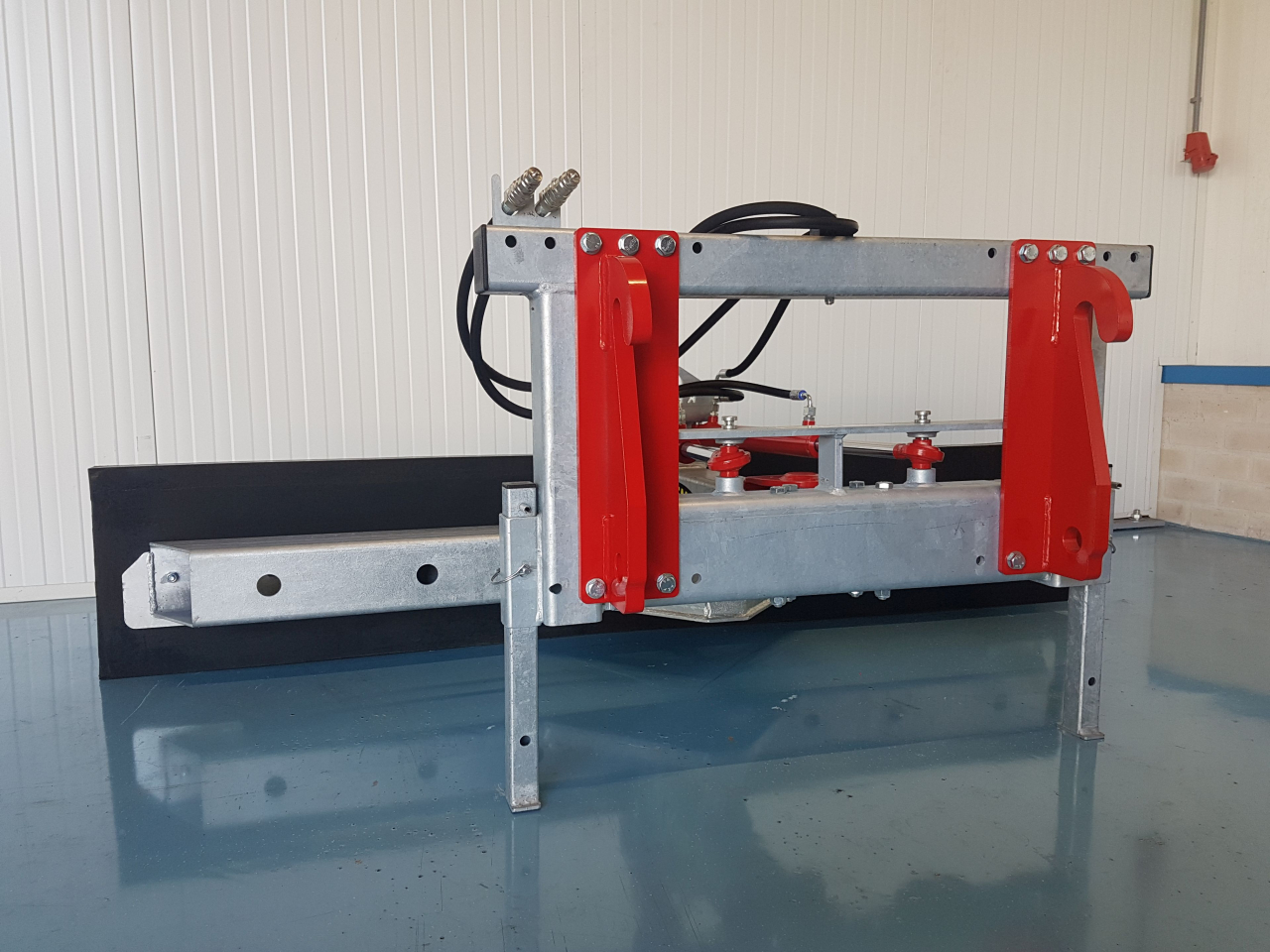

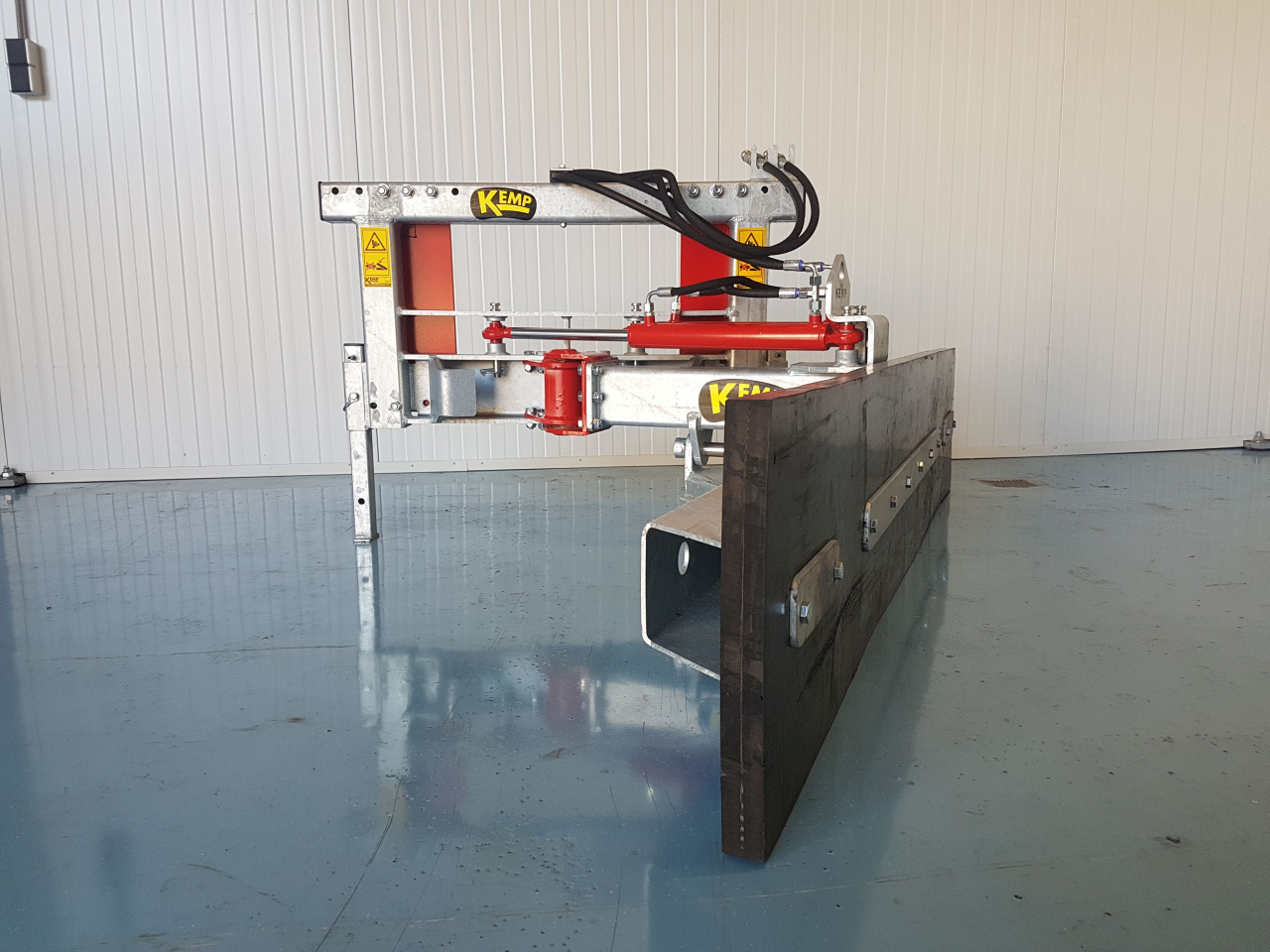

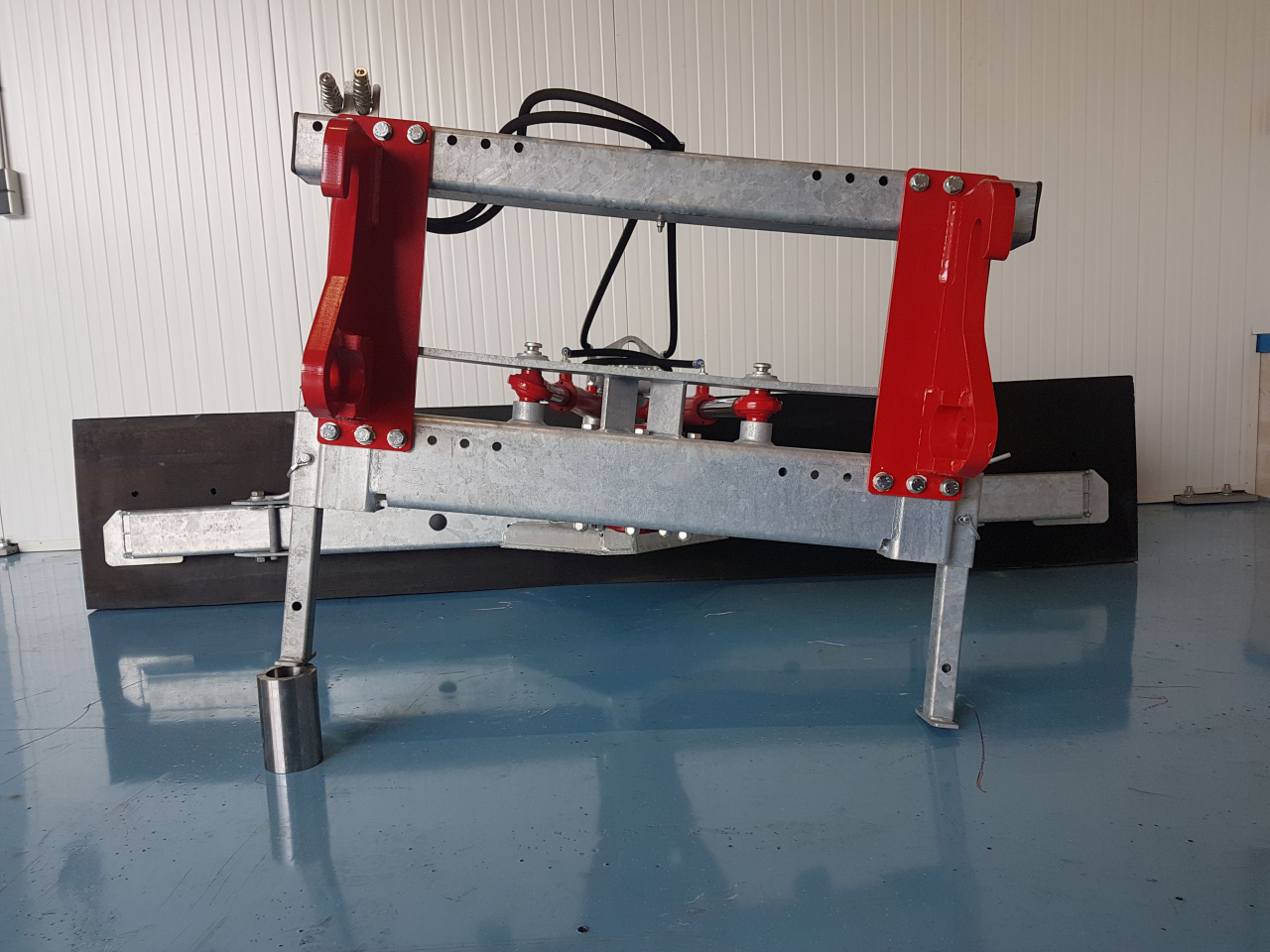

The galvanized feed alley scraper is, like the other Kemp feeders, capable of swivelling 70 degrees, left and right. Because the slide swings 70 degrees, the feed can be slide well towards the cows and it will not start to accumulate. In addition, it is important that the feed is placed next to the vehicle, so that the vehicle does not drive over the feed. Therefore, it is important that the scraper can pivot. Pivoting 70 degrees is possible through the use of two hydraulically driven cylinders. The second advantage of these two cylinders is that there is more power to pivot the scraper during feeding.

The next advantage of the Kemp feed scrapers is that they can oscillate. This means that the rubber strip can move with respect to the mounting frame. The advantage is a good ground adaptation and uniform wear of the rubber.

It is important that the feed is pushed next to the vehicle. The slider is thus available in several sizes, so that there is a suitable scraper for every vehicle.

The core task of the feed sliders is of course the feeding of feed, however, the slide can also be used as a mud slide, snow blade, to slide away any residual feed or to push the sand away on the silage pit.

The RVS differs from other feed scraper with the fact that it is completely galvanized. Due to this galvanize layer, the scraper is no longer sensitive to weather influences and influences of maize and the like.

The second distinction is the demountable rotary bush. Despite the fact that the pivot point is made with teflon-coated bushings, the point where the slide rotates has the greatest chance of wear. Because of this, this point is dismountable, a new swivel can be placed.

The galvanized rubber feed scraper is available in several sizes, in order to offer a suitable model for every vehicle. With the larger sizes, the rubber is of course longer, which means that there are greater forces on the machine. In order to be able to guarantee the quality; the frame, cylinders and rubber are improved in the larger sizes.

The type number for the smaller rubber scraper is RVSS and for the larger rubber scrapers RVSL. The RVSS is available in sizes 2,200 mm and 2,500 mm. The RVSL in sizes 2,500 mm, 2,800 mm and 3,200 mm.

The RVSS has cylinders of 40*25*300 mm and the RVSL cylinders of 50*35*350 mm. The rubber of the RVSS is 400 mm high and 40 mm thick and the RVSL 500 mm high and 50 mm thick. In this higher rubber two rows of holes are drilled, allowing you to turn over or lower the rubber when one side is worn.

The RVSS is about 290 kg, due to the adjustments in the frame, the larger cylinders and the heavier rubber is the RVSL 380kg.

The RVSS is suitable for a vehicle that is at maximum 1,60 meter width. The RVSL is suitable for a vehicle that is at maximum 2,20 meter width.

The galvanized feed alley scraper is available with the attachments that belong to your vehicle (for the attachment parts, see the document: Kemp attachment parts).

For additional specifications, see the document: product specifications.

Options:

Adjustable angles (manually): The feed scrapers are standard equipped with a straight beam, however it is also possible to choose for manually adjustable angles. These angles can be adjusted 35 degrees with respect to the beam. The adjustable angles give you more control to keep the feed near the rubber and thus slide away in the direction of travel.

Extra rubber strengthening: When you choose adjustable angles, you also have the option of adding an extra rubber reinforcement to the corner. This makes the corners firmer and reduces the chance that the rubber bends over and tears later.

Shock valve: a shock valve is needed with vehicles above 4,000 kg. The shock valve provides protection when the scraper collides with something. In this case, the shock valve ensures that the oil from the cylinder, which has come under pressure, is moved to the other cylinder. As a result, the scraper swings past the obstacle and the chance of damage is reduced. The shock valve is of course only possible with two cylinder scrapers.

Pilot operating non return valve: Needed at open centre and internal leakage control valve. Duo to the open centre, the oil can’t be blocked and the scraper can’t stay in one position. The pilot operating non return valve, takes over this function by blocking the oil flow, allowing the scraper to stay in one position.

Another possibility is a throttling to control the speed of pivoting. This gives you more control when hydraulically slewing the scraper.